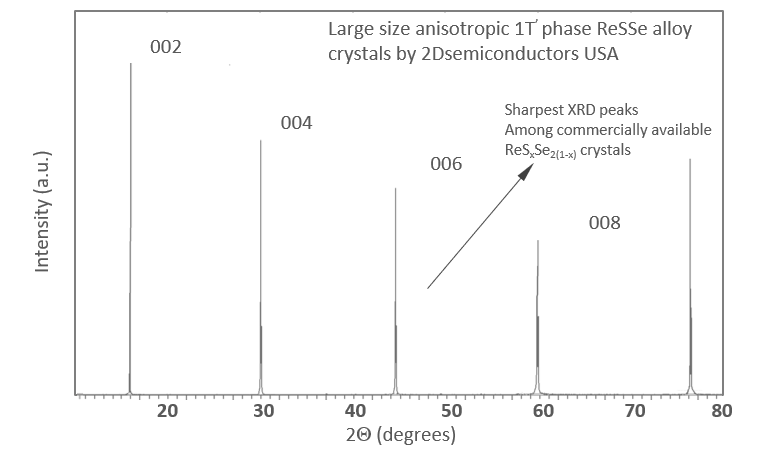

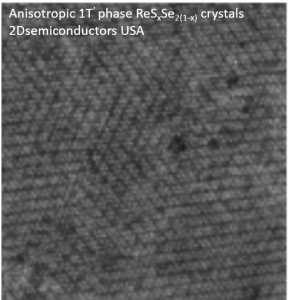

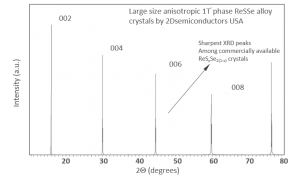

Single crystal ReSxSe2(1-x) alloy rystals are developed at our facilities using chemical vapor transport or flux zone technique methods. Our ReSSe2 crystals display impressive structural anisotropy from bulk down to monolayers as evidenced by TEM and angle resolved Raman spectroscopy measurements (see XRD, TEM, Raman, PL, and other figures below). Crystals are perfectly layered, and ready for exfoliation. Our R&D team also provides you with transfer technique to boost your monolayer yield rate up to 95%. Alloys are 100% guaranteed to anisotropic and homogeneously alloyed (not phase separated).

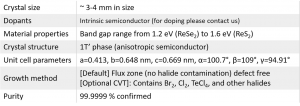

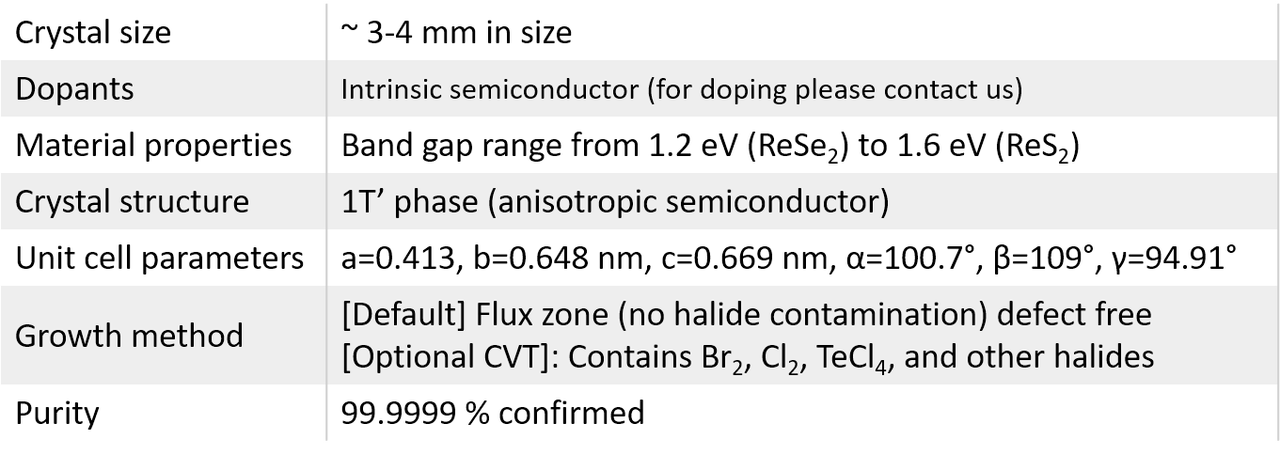

Typical characteristics of ReSSe2 alloyed crystals from 2Dsemiconductors

、

、

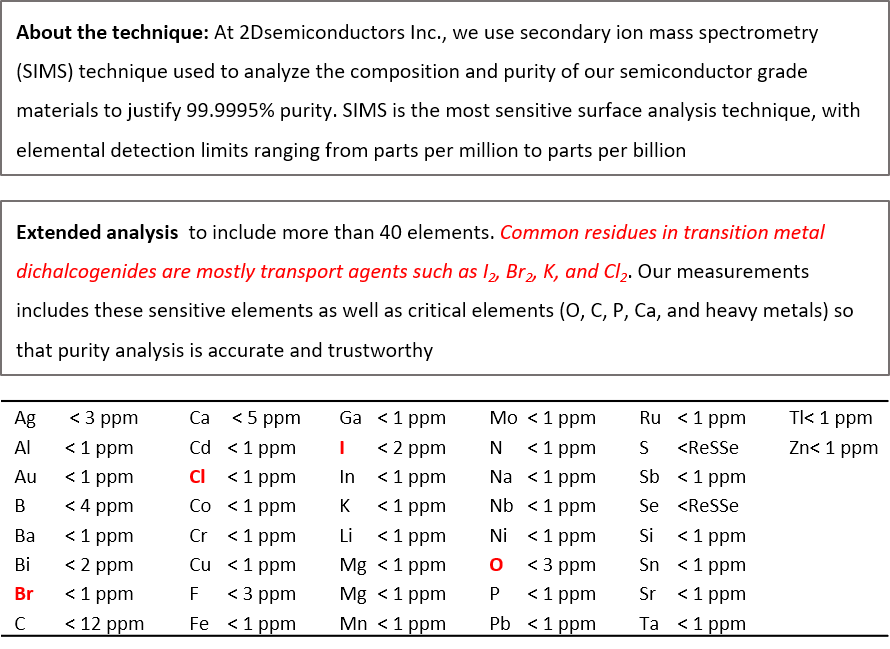

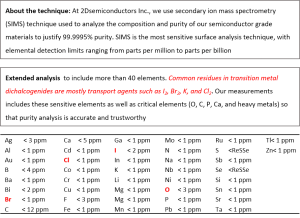

Growth method matters> Flux zone or CVT growth method? Contamination of halides and point defects in layered crystals are well known cause for their reduced electronic mobility, reduced anisotropic response, poor e-h recombination, low-PL emission, and lower optical absorption. Flux zone technique is a halide free technique used for synthesizing truly semiconductor grade vdW crystals. This method distinguishes itself from chemical vapor transport (CVT) technique in the following regard: CVT is a quick (~2 weeks) growth method but exhibits poor crystalline quality and the defect concentration reaches to 1E11 to 1E12 cm-2 range. In contrast, flux method takes long (~3 months) growth time, but ensures slow crystallization for perfect atomic structuring, and impurity free crystal growth with defect concentration as low as 1E9 - 1E10 cm-2. During check out just state which type of growth process is preferred. Unless otherwise stated, 2Dsemiconductors ships Flux zone crystals as a default choice.