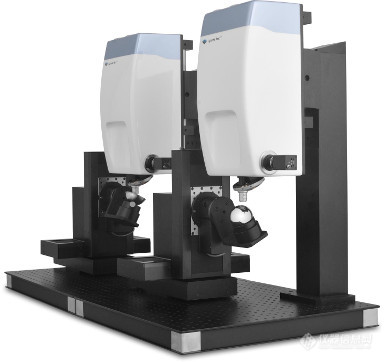

Lyncee Tec 高速光学三维质量检测仪

On-flight measurement up to 15 cm/s

3D Optical Inspection by DHM® is a unique 3D imaging solution compatible with production environment. DHM® allows optical inspection of 3D topography, surface finish, defect detection of moving samples at high throughput on production floors, in presence of environmental noise and vibration.

Measurement on Production Floor

Sample displacement up to 35 cm/s

Measurement rate up to 100 Hz

No need of anti-vibration working station

Numerical Reconstruction

Digital sample focusing without mechanical adjustment

Tilt-tip correction performed digitally

3D measurement with metrological precision and stability

Traceability : intrinsic vertical calibration

Reliable instrument : no complex scanning mechanism

Saw marks detection on a solar wafer 1 wafer per second, measurement area 5 mm x 150 mm

Saw marks detection on a solar wafer 1 wafer per second, measurement area 5 mm x 150 mm

High throughput measurement is possible with DHM® unique non-scanning technology. DHM® high acquisition rate enables measurement of a large quantity of samples and products directly on the production line. DHM® short acquisition time makes the system robust against vibrations.

DHM® is a reliable system with low maintenance costs since there is no complex scanning mechanism inside the microscope. DHM® intrinsic vertical calibration makes the vertical measurement accurate over time.

Depending on user needs, DHM® are mount on a standard column or integrated on user’s infrastructure (conveyor tray, gantry). Such system is usually customized and dedicated to a specific inspection. DHM® can be controlled by the TCP/IP software module enabling control of all the acquisition and analysis function of DHM®.

Nanometer faster than ever

DHM® is the only technology providing a reliable 3D measurement at high throughput. 3D Optical Inspection offers you significant benefits in terms of production quality, time saving and innovation.

Save time & cost through…

Detect failure early in the process and avoid expensive recalls

Reduce your maintenance costs, use DHM® instrument that has an intrinsically stable reference and requires only limited calibration

Have long MTBF (mean time between failure) thanks to the absence of complex scanning mechanism

Innovate to keep your competitive advantages

Be a pioneer making 3D measurement at high throughput and on production floor

Access a new dimension with unique DHM® optical information, all DHM® innovative solutions are compatible with industrial inspection

Control roughness according to ISO standard

Measure areas larger than the field of view with fast and automated stitching

Use an instrument adapted to the industrial environment

Ease of automation and integration in your IT production system

Limited training required as the system is adapted to production operator use

Modular DHM® head can be mounted on your production line or integrated in your instrument

3D measurement on production floor thanks to the robust and reliable system

Application Cases

For industrial 3D optical inspection, the first system installed by Lyncée Tec was dedicated to quality control in the watch industry. An important step has been achieved in 2010 by demonstrating measurement on a convey tray, i.e measurements without stopping the sample, and without any mechanical adjustment of the height of the sample for focalization.

DHM® is currently used for 3D optical inspection in semiconductor, medical technology, watch, and solar industries, for controlling among others the following features:

Topography

Roughness measurement according to ISO standard

Step height of SiO2 on Si wafers

Sample’s aesthetic control

Roughness inspection according to ISO standard