详情

Lyncee Tec MEMS全息测振分析仪

探索精彩的4D世界

全息MEMS测振分析仪记录MEMS振动周期中的三维形貌时序图,为MEMS振动测量提供了 的丰富数据,特别是可以在被测视场内任意一点测量面内和面外振幅(位移)及频率响应,这些独特优势与完善的配套软、硬件一起提供了一套完整的MEMS振动测量解决方案。

非扫描式测量,大大缩短表征时间

使您能够有效比较模拟仿真与实际器件测量结果

独有的全息技术助您获得其他测量技术无法实现的数据

实时呈现器件响应:

With a single instrument

一套完整的解决方案:从测量 …

Lyncée Tec的全息MEMS测振仪拥有包括软、硬件在内的一整套完整的解决方案:

可加热样品探针台

可温控真空腔

MEMS信号激励,可达 25 MHz

记录器件电学响应

DHM® 记录三维形貌时序图

频闪模块同步测量信号

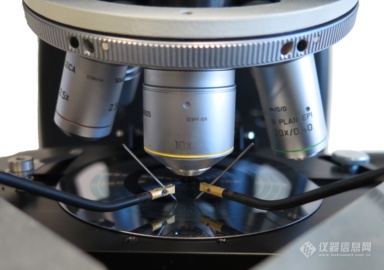

Wafer probing under the DHM®

Wafer probing under the DHM®

… 到时序图分析

MEMS专用分析软件MEMSAnalysis Tool 能够实现高效的三维时序图分析:

离面运动测量幅值从 5 pm 至 50 microns

面内运动测量幅值从 1 nm (子像素算法) 至 5 mm

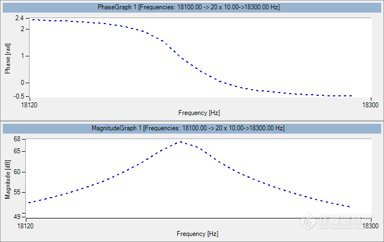

伯德和傅里叶频域分析

多器件振动测绘、模态图

Bode diagram

Bode diagram

用户反馈

Users Testimonials

University Autonome of Barcelona

An international team of researchers from Spain, the Netherlands, and USA have characterized the flexoelectric coefficient of dielectric materials on silicon by measuring the bending radius induced on application of voltage, with the DHM®.

Nature publication

Nature Nanotechnology 11, 263–266 (2016) doi:10.1038/nnano.2015.260

Nature Nanotechnology 11, 263–266 (2016) doi:10.1038/nnano.2015.260

The DHM, unlike a vibrometer, directly measures the out of plane displacement induced at each point of a MEMS structure during a vibrational excitation .

Dr. Umesh Kumar, first author

Thus, the DHM data lends itself elegantly to harmonic analysis via the application of discrete Fourier transform techniques. The latter is indispensable to distinguish between a response that scales linearly with the applied electric field (for example, piezoelectric strains) and a response that scales quadratically with the applied electric field (for example, electrostictive strains).

FHG-IPMS in Dresden, and TU Cottbus Senftenberg

German researchers from FHG-IPMS in Dresden, and TU Cottbus Senftenberg have measured the deflection of a revolutionary micro-actuator technology using DHM® (IPMS-FHG press release).

Nature publication, Electronic Component News

Nature Communications 6, Article number: 10078 (2015) doi:10.1038/ncomms10078

Nature Communications 6, Article number: 10078 (2015) doi:10.1038/ncomms10078

We can work with any dynamics we want (stroboscopic and continuous measurement) – that makes the DMH unique to alternative tools (WLI and Laser-Doppler-Vibrometer).

Conrad Holger, first author

It gives the high vertical resolution to precisely characterize the actuator out of plane deflection

A vibrometer measures a velocity using the Doppler effect: tip deflection is calculated by an integration. Consequently, position measurement errors are also integrated, preventing absolute prosition and long term drift measurements.

Dr. Matthieu Gaudet

DHM® doesn’t suffer from this problem as it measures directly a position. Deflection can be measured accurately for any time scale.

系统构成:

Holographic MEMS Analyzer

The Holographic MEMS Analyzer solution encompasses all the options to provide you with a complete environment for MEMS characterization. The system responds to most users characterization needs, however if something is missing, Lyncée Tec is also pleased to provide you with turnkey customized solutions.

Probing

MEMS probing platforms enable direct DHM® characterization of devices without wire-bonding. A heated version enables the investigation of the effects on MEMS responses of temperatures up to 200°C.

Vacuum and temperature control

Vacuum & thermal chambers enable characterization of devices in real conditions of use, e.g. vacuum, liquids, gas, high and low temperature, down to 196°C, high pressure, etc. Measurements are as simple as in ambient conditions thanks to DHM® unique optical configuration.

Holographic Microscopes

Reflection and transmission DHM® with one and two wavelengths are fully compatible with the Holographic MEMS Analyzer solution. They can be configured with any objective, including long working distances, immersion, and glass corrected models, for measuring in presence of probes, in liquid, and through transparent covers respectively.

Stroboscopic Module

The stroboscopic unit synchronizes the MEMS excitation with the 3D topography time sequence and electrical response measurements. is recorded to get 3D topographies time sequences along the excitation of the MEMS, vibration and electrical information in a single data set with one system.

Post-analysis software

The MEMS Analysis Tool software enables movement decomposition in terms of tilt, deformation, in- and out-of-plane displacements. Vibration amplitude, speed and acceleration at any location of the sample can then be calculated. Moreover, this software enables resonance, Fourier, and Bode frequency analysis.

Competitive strengths

Holographic MEMS Analyzer overcomes limitations of usual MEMS analyzers. It is the only solution able to synchronize MEMS excitation and 3D topography measurement at frequencies up to 25 MHz. Moreover, it is ideal to measure in any environmental condition.

Alternative systems are :

Laser Doppler Vibrometer : LDV

White Light Interferometer : WLI

2D stroboscopic microscopy

Holographic MEMS Analyzer vs Laser Doppler Vibrometer (LDV & 3D LDV)

The main difference between both systems is that the DHM® retrieves simultaneously data points on each pixel on the entire field of view while LDV scans the surface point by point.

Therefore LDV lateral resolution is limited by the spot size (few microns). With DHM® you can select the lateral resolution adapted to your sample by choosing the appropriated objective.

LDV has to perform a complex chain of signal processing steps to measure a velocity. Each data point is then converted in term of vibration amplitude. LDV alone does not provide an absolute position and thus no 3D topography. DHM® measures a time sequence of successive 3D topographies what enables direct calculation of absolute position, speed and acceleration. Vibrations amplitude can be determine with high reliability by DHM®.

| Features | DHM® | 3D LDV | LDV |

| Dynamic topography | √ | × | × |

| 3D vibrations (X,Y,Z) | XYZ | XYZ | Z only |

| Maximum frequency | 25 MHz | 25 MHz | up to 1.2 GHz |

| Full field measurement | √ | with XY scanning | with XY scanning |

| Diffraction limited resolution | √ | limited by laser spot size | limited by laser spot size |

| Objective turret | √ | × | × |

| No need of sample preparation | √ | – |

× |

| Measurement of complex structures | √ | × | × |

| Measurement of complex motions (simultaneous in-, out- of plane, tilt, … ) | ++ | – | – |

| Measurement of in-plane displacement lager than MEMS structures | √ | × | × |

Holographic MEMS Analyzer vs 2D Stroboscopic Microscopy

2D stroboscopic microscope is usually combined with LDV to add in-plane displacement measurement capabilities to vibrometer.

| Features | DHM® | 2D Stroboscopic Microscopy |

| 3D topography | √ | × |

| 3D vibrations (X,Y,Z) | √ | × |

| Maximum frequency | 25 MHz | 1 MHz |

| Full field measurement | √ | × |

Holographic MEMS Analyzer vs White Light Interferometer (WLI)

Some white light interferometers can perform a stroboscopic acquisition to measure MEMS dynamic topography. However, measurements of dynamic sample with a scanning technology are sensitive to environmental noise, i.e. vibrations, and are time consuming.

Some systems combine white light interferometer with LDV or 2D stroboscopic acquisition in order to measure a static topography. In this case measurements of topography in environmental chamber face usual limitations of WLI technology.

| Features | DHM® | WLI |

| Dynamic topography | √ | × |

| 3D vibrations (X,Y,Z) | √ | × |

| Maximum frequency | 25 MHz | 1 MHz |

| Stitching measurement | √ | not in stroboscopic mode |

| Measurement in environmental chamber | √ | × |

Specifications

| Optical measurement unit | Reflection DHM® or Transmission DHM® |

| MEMS excitation unit | LyncéeTec stroboscopic module |

| XYZ stage | Manual or motorized stage |

| Software | Koala for acquisition and live analysis

MEMS Analysis Tool for advanced post-analysis |

| Objective | Turret with 6 positions, magnification from 2.5x to 100x |

| In-plane vibration2 | from 10 nm to 5 mm |

| Out-of-plane vibrations2 | from 10 pm to 50 μm |

| Topography resolution |

Vertical : 0.1 nm

Lateral1 : from 400nm to 8.5μm |

| Excitation frequency | from static to 25 Mhz |

| Laser pulse length | down to 7.5 ns |

| Max vertical velocity2 |

up to 10 m/s |

1. equivalent to vibrometer spot size, objective dependent

2. specification does not depend on excitation frequency

陈谷一

陈谷一